Dorner’s ability to create the perfect solution for almost any application has been the defining factor that positioned us as an industry leader for over 55 years. We strive to offer one of the widest conveyor portfolios on the market today and build innovative material handling systems to improve our clients’ operations. Our diverse collection of pallet system conveyors is designed to be both accurate and versatile to fit your application.

As with any capital investment, it’s important to carefully consider the various features offered by different conveyor systems to determine which is best for your application and meets your requirements.

Questions to consider:

- What is my product weight and size?

- Does the operation require cleanroom certification?

- What speeds will the line need to run at?

- Will products be transferred from machines or between conveyor lines?

While there may be many more questions to answer these are just a few that will help you in deciding which Dorner pallet system is best for your application.

Overview of Dorner’s Pallet Systems

DualMove

The DualMove is the newest pallet system that utilizes twin timing belts to precisely move pallets into the right spot at the right time. DualMove properly stages pallets by utilizing accessory modules such as lift and transfer, lift and rotate, and lift and locate. These modules can precisely place, orientate, and move products wherever your application needs them. This pallet system accelerates productivity in assembly lines and assists in precision assembly and integration with robotics.

DualMove conveyors provide a cost-competitive precision conveyance solution for a wide variety of industries. This product is great for numerous applications including small appliances, fitness equipment, electronic assembly, packaging, and more.

DualMove Specs

- 25 mm wide belting

- Pallet widths: 160, 240, 400, 320, 400, 480, 640, and 800 mm

- Custom widths available

- Lengths: 275-7500mm in 5 mm increments

- Load capacity up to 227 kg (500 lbs) non-accumulating

- Speeds up to 66 mpm (215 fpm)

- T10 timing belts with steel cords available in low-friction, medium-friction, and static-conductive options

- 19 tooth 60.6 mm pitch diameter drive sprocket

- Mid drive available in any location along the conveyor rails starting at 30 mm from each end

- T-Slots along frame for easy hardware and accessory mounting

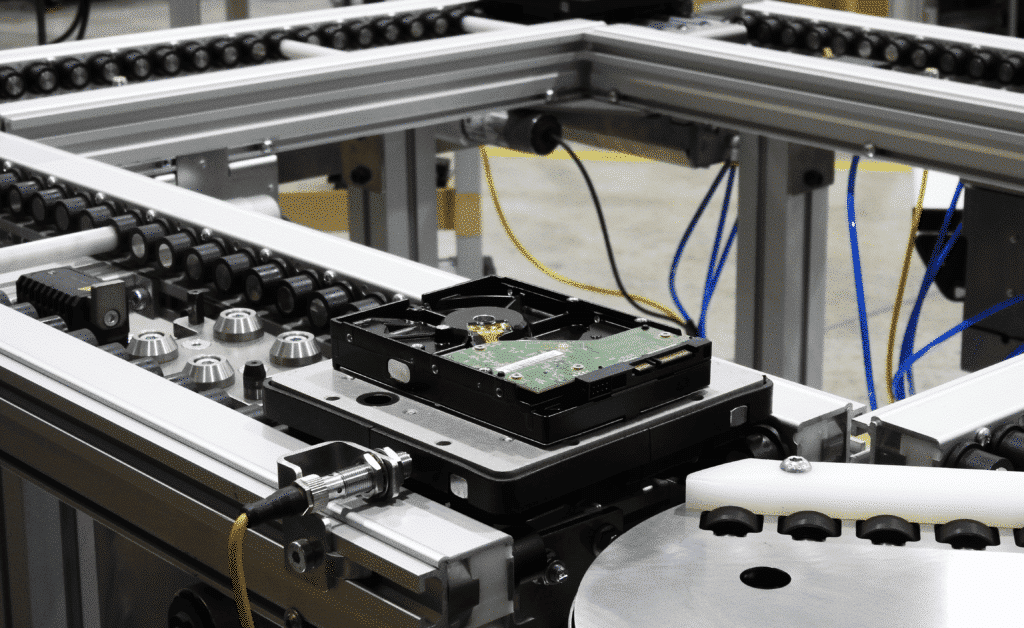

ERT 150/250

The ERT series are precision edge roller pallet and tray handling conveyors. The ERT is designed for applications that require differing levels of certifications and control elements. These conveyors are verified up to ISO Class 4* requirements, which is critical for applications such as production of medical devices and electronics. Non-contact zone control provides simplified traffic control that eliminates pallet stops and costly pneumatic valves. Conversely, slip rollers can be used for full length runs with conventional pneumatic pallet stops. The rollers are easily accessible and can quickly be replaced without affecting the remaining portion of the conveyor. The ERT also features a control infrastructure with a 24-volt DC motor. This low voltage control system works in conjunction with network connection, making it easy to integrate into an existing production line.

Specs ERT 150

- Pallet widths: 160 – 320mm

- Conveyor Widths: 80 – 480mm

- 24mm diameter rollers on 32mm centers

- Load capacity up to 16 kg (35 lbs) per pallet or tray

- Speeds up to 37 mpm (121 fpm)

Specs ERT 250

- Pallet widths: 320 – 800mm

- Conveyor Widths: 120 – 960mm

- 38mm diameter rollers on 50mm centers

- Load capacity up to 114 kg (250 lbs) per pallet or tray

- Up to 6.8 kg (15lbs per roller)

- Speeds up to 37 mpm (121 fpm)

FlexMove Pallet Systems

FlexMove Pallet Systems utilizes the versatility and flexibility of FlexMove technology and pairs it with the precise product handling that a pallet system can offer. This pallet system can use both diverting and merging technology to move products down different portions of the line to maneuver differing products and get them quickly and accurately through the fulfillment process.

Specs FlexMove Pallet Systems

- Pallet widths: 190mm

- Conveyor Widths: 105mm (4in)

- 38mm diameter rollers on 50mm centers

- Load capacity up to 114 kg (250 lbs) per pallet or tray

- Up to 6.8 kg (15lbs per roller)

- Speeds up to 37 mpm (121 fpm)

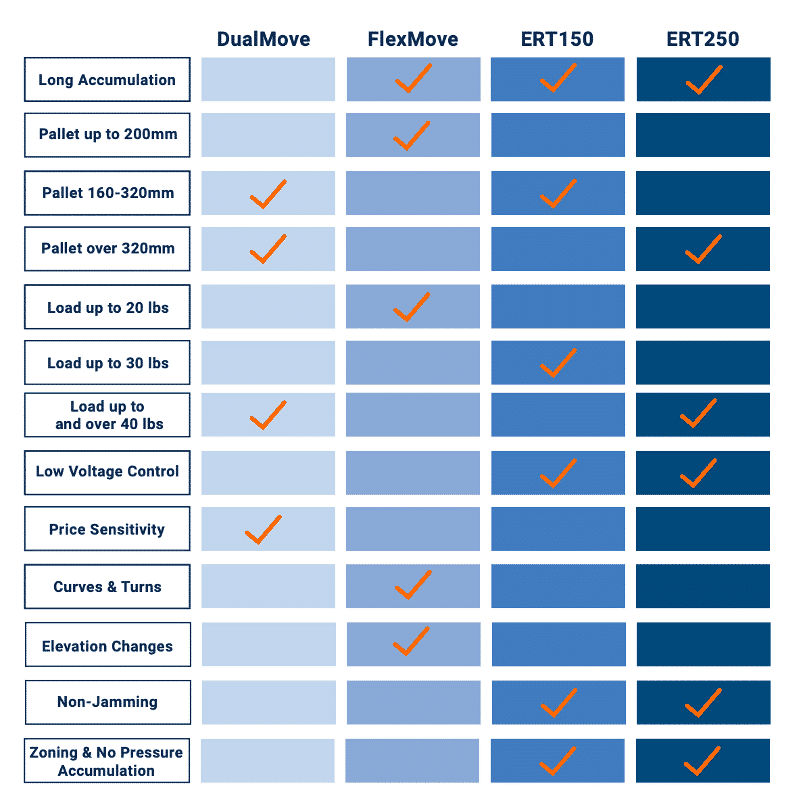

Pallet System Features Comparison Chart

Choosing the Right System:

Taking the time to understand the requirements of your product and application are vital to choosing the pallet conveyor system that is best suited to your operation. Our team of conveyor experts works with you to evaluate your unique needs and build a conveyor system that meets your exact requirements.

The system itself is critical, but the partnership with the automation provider is something that is commonly overlooked. Customer service, service materials, and readily available spare parts are just a few of the things that are critical in minimizing downtime and achieving maximum efficiency.

Here are some other factors you may want to consider:

- Do you need a system that can work with robotic integration?

-

- Dorner Match: Any

- Does the application require cleanroom standards?

-

- Dorner Match: ERT150 or ERT250

- Do you plan on transferring pallets to another line during production?

-

- Dorner Match: Lift and Transfer Modules

- Are your products particularly heavy or bulky?

-

- Dorner match: ERT250 or DualMove

- Do you need a flexible solution to curve around machinery or change elevation?

-

- Dorner Match: FlexMove

These are just some of the questions that a Dorner quoting expert will discuss with you in order to tailor the right solution for you.

If you are looking for a solution, please contact the automation experts at Dorner for more information info@dorner.com.